Termaks

Laboratory Drying Ovens

Termaks forced convention drying and heating chambers for fast drying and sterilization. Designed for excellent temperature distribution with variable fan settings temperature the entire range offers very high temperature stability up to +250°C.

High lights

- Temperature range up to +250°C

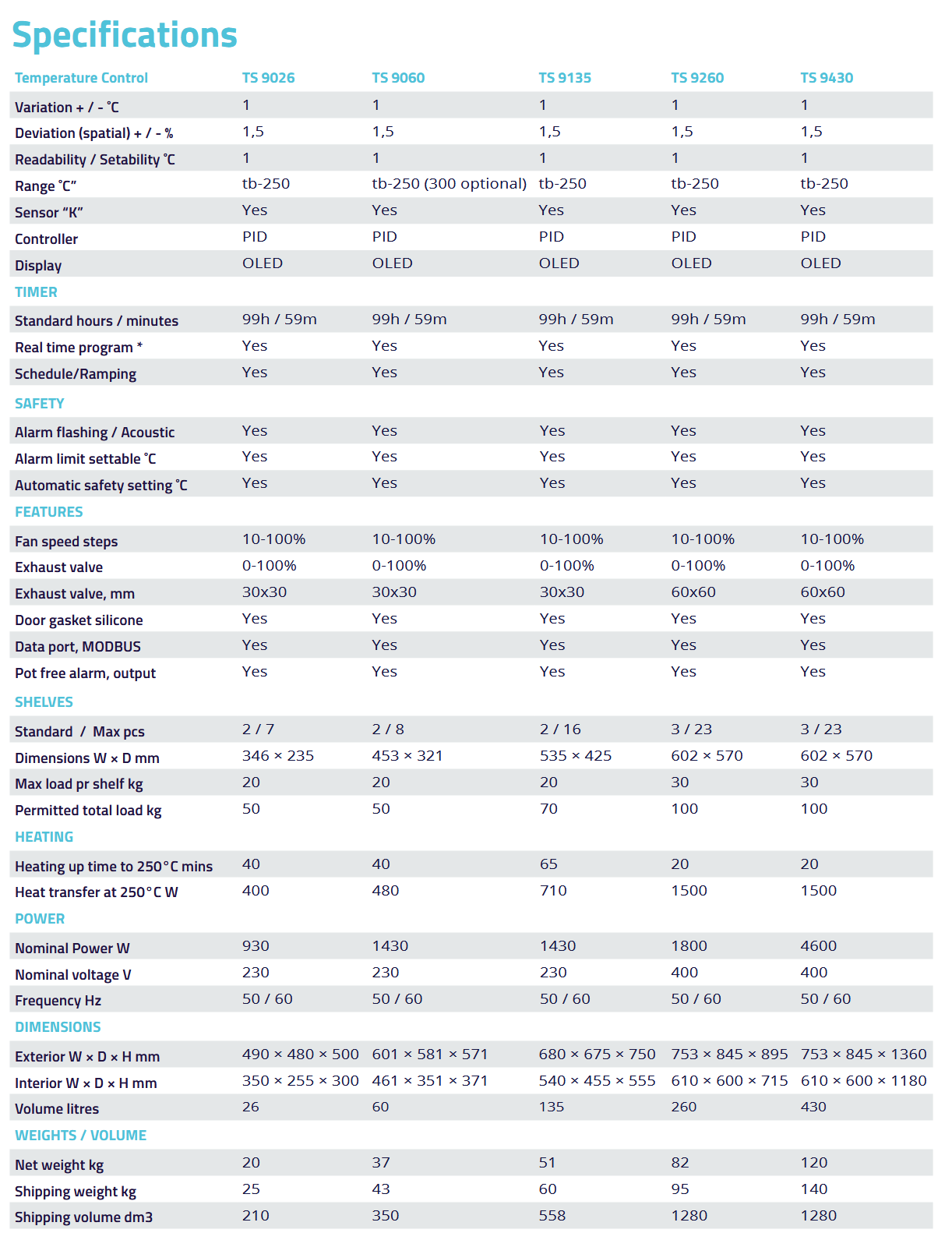

- 4 model sizes (26 to 430 litres volume)

- Stackable B9026/9053/9135, optional stacking kit

- Forced air circulation

- Automatic and programmable electrical Air valve

- Safety thermostats and redundant system for maximum protection

- Data logging and Remote support via Connect

- Access ports for data logging with external sensors (optional)

- Castors, lockable for increased mobility (B9430)

Termaks incubator TS-Series is ideal for all applications within drying and sterilization and temperatures up to +250°C. The newly developed control system allows fine tuning at any temperature in the range.

The control system is designed in accordance with EN61010 and has been EMC-tested in accordance with EN 60730-1 and EN 60730-2-14.

The control system is designed in accordance with EN61010 and has been EMC-tested in accordance with EN 60730-1 and EN 60730-2-14. Termaks cabinets can be controlled via CTS, PC or Gateway allowing data logging, event log and more to be stored The system software can be updated directly on the PCB, through the SD-card slot and it is also possible to upload new setpoint files this way.

The TS-series is also available in a version with H14 HEPA filtration on inlet air inner.

Automatic safety thermostat Increased safety – simpler to operate

OLED display Explanatory text – simpler to operate

Touch buttons Extended lifetime in humid surroundings

Software Alternates between two temperatures at specified time, daily or weekly

Extended temperature range Can operate down to 2°C above ambient temperature

Keypad with PIN code Prevents undesirable settings

Potential free alarm contact Can connect to external alarm system

Remote support and logging via Connect

MODBUS communication

Variable fan speed

Electrical controllable Air valve Optimizing drying processes

Advantages:

- Precise performance

- Real time programming

- Intuitive and easy-to-use control panel

- Air exchange rates and air valve position electronically controllable

- temperature ramps programmable via display or Connect

- high-quality, corrosion-resistant and chamber in stainless steel for easy cleaning

- state of the art heating for a precise and homogenous temperature control

- Safety thermostats and redundant system for maximum protection

- Reliable